What is additive manufacturing?

Additive manufacturing or generative manufacturing processes or in English: additive manufacturing (AM) is a general term for all processes that offer a cost-effective and quick way to produce prototypes and models, but also end products. The term is usually used as a synonym for 3D printing, but the term additive manufacturing makes it even easier to understand that this is a professional process. In additive manufacturing, the component is manufactured by adding the material layer by layer. Additive manufacturing is a professional production process that is the opposite of conventional ablative manufacturing methods. With abrasive manufacturing methods, for example, the model is milled out of a solid block of material. With additive manufacturing, on the other hand, the model is built layer by layer from the materials. Materials can be, for example, different metals, plastics or composites. Additive manufacturing is often used as part of rapid prototyping, i.e. in the production of prototypes in industry.

Features/Benefits of additive manufacturing

- Tool-free production – no tools are required in the production of components, which means that the one-off costs are almost non-existent.

- Comprehensive design freedom – even complex models can be manufactured

- Flexibility – on-site and on-demand production

- Scalability – series or individual production

- Shorten product development and time to market

- Possibility of ongoing adjustments even during ongoing series production

- Manufacturing of products on a microscopic scale (e.g. in medical or electrical engineering)

- High quality and cost-effectiveness

- Saving resources

- Geographically independent (no large production sites or large tools are required)

- Customizability of products – Products can be customized to suit the customer at no additional cost

Advantages of additive manufacturing

Conventional manufacturing, such as milling, drilling or turning, often reaches its limits. Some designs cannot be implemented using conventional technologies. Additive manufacturing enables a “design driven manufacturing process”. This means that the design is no longer determined by the manufacturing method, but vice versa. With the help of additive manufacturing, even very complex models can be manufactured that are still extremely stable.

Areas of application in 3D printing

The basis for additive manufacturing is a CAD file (Computer Aided Design) with digital construction data. Areas of application in 3D printing are very different. Below is a brief overview of the most important areas:

- Prototype construction

- Series production

- Educational institutions

- Tool and fixture construction

- Mechanical engineering

- Automotive

Professional production with 3D printers

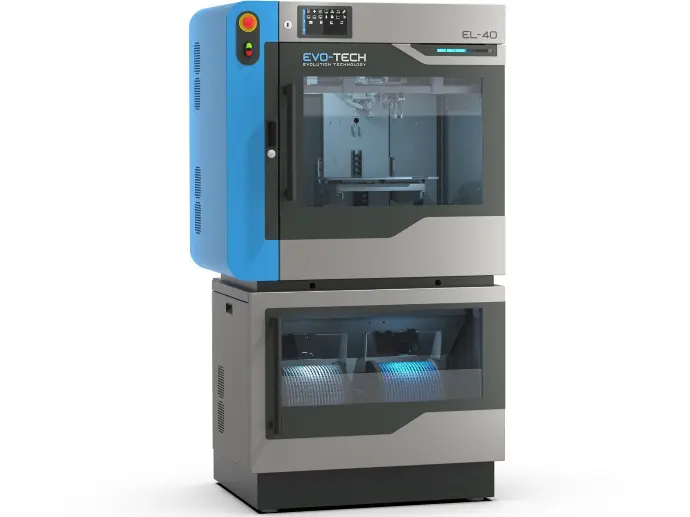

3D printer EL-40

nables the creation of parts up to 270 x 200 x 210mm (W x D x H) with extremely low operating costs and an open system for filaments.

3D printer EL-140

Enables simultaneous printing of multiple parts and the processing of large quantities of material up to a size of 570 x 450 x 570 mm (W x D x H).

Additive manufacturing process

The principle of additive manufacturing is a step-by-step structure in which the material is applied layer by layer. Depending on which process was chosen and which materials are used, the structure is different.

Fused Filament Fabrication

Fused Filament Fabrication (FFF) involves printing plastic (especially ABS or PLA) using melted plastic wire. The added material is melted by a heated extruder and applied to a heated print bed. The workpiece is manufactured line by line and layer by layer, with the next layer only being applied once the previous layer has solidified. This process has the largest possible range of materials that can be processed. The EVO-lizer 3D printer also uses the FFF process for 3D printing. The following video explains the process of melt layering using the NEVO3D 3D printer..

3D powder printing

Different materials are suitable for 3D printing with powder. Printing is primarily done with plastic or plaster, but glass, ceramic or other powdered materials are also suitable. Similar to a conventional inkjet printer, a 3D printer also works with print heads. These are used to apply liquid glue in small amounts to a layer of powder. The powdery substances harden and stick the layers of the piece together. This is how the model is created layer by layer.

Selective laser melting (SLM)

With selective laser melting, the material is not connected by a binder, but rather melted using a high-power laser. This process can also be used to produce metal workpieces.

Electron Beam Melting (Electron Beam Additive Manufacturing)

This process is comparable to selective laser melting, where an electron beam is used as the energy source instead of the laser.

Stereolithography

In this manufacturing process, the models are built in a basin filled with liquid photopolymer. A laser projects the layers of the model onto the surface. The liquid photopolymer solidifies after a certain exposure time, forms the first layer and bonds to the print bed underneath. The print bed is then pulled down and the next layer is built up.

Digital Light Processing (DLP)

The functionality corresponds to that of stereolithography, but a DLP projector is used as the light source.

Multi Jet Modeling (MJM), Polyjet process

MJM is a hybrid of stereolithography and conventional 2D printing. A liquid plastic is applied to a platform and immediately hardened using a light source integrated into the push button. This process is very detailed.

Film Transfer Imaging Process (FTI)

FTI works similarly to the MJM process. A transport film is used here: the liquid plastic is applied with it.