In this tab the settings for the temperature of the build platform and the extruder are made. The processing temperature is the most important process parameter and should be adjusted accordingly carefully.

Hot-End Temperatur

A temperature that is too high leads to smeared components, “ stringing ” and, in the worst case, thermal degradation of the plastic, which can also lead to the formation of toxic fumes. If the temperature is selected too low, insufficient layer adhesion, insufficient extrusion or the extruder motor slipping or the filament rubbing can occur. The extrusion temperature of the first layer also influences how well the component adheres to the printing platform. There is usually no exact ideal temperature for 3D printing. Rather, there is a temperature range in which the plastic can be processed. In general, it can be said that at the lower end of the temperature range better results can be achieved in terms of detail and appearance of the component, while at the upper end better layer adhesion and component stability can be achieved. However, this still depends on other processing parameters.

Plattformtemperatur

The temperature of the build platform plays a large role in how well the component adheres to it. If the temperature is too low, the component will detach from the build platform after a few printed layers. If the temperature is too high, the component gets a so-called elephant's foot, the first layer protrudes above the rest of the component. This effect occurs when the first layer of the component is firmly anchored on the construction platform, but the layers above can deform due to the radiated heat and shrinkage occurs.

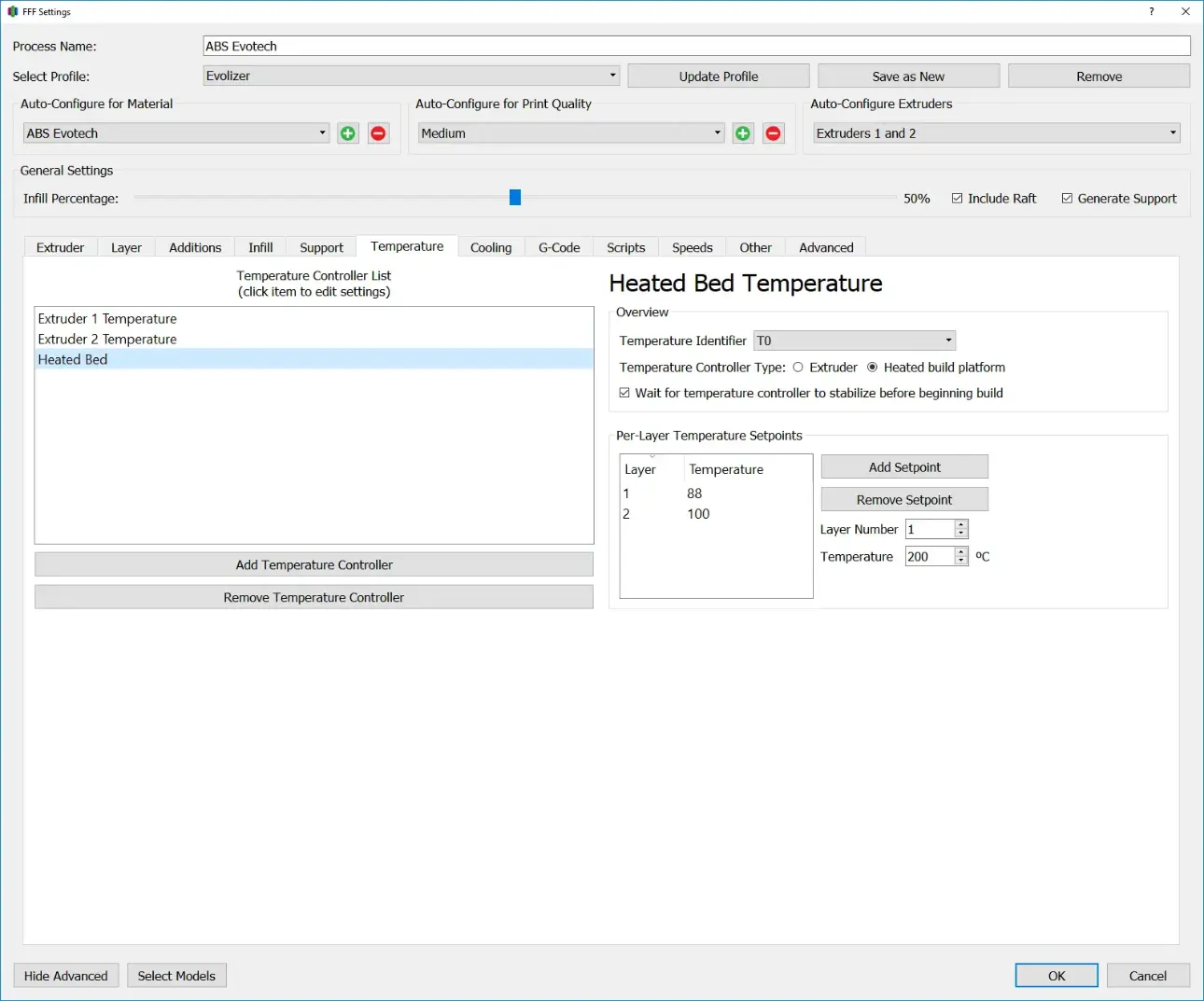

Overview

Temperature Identifier

Indicates which sensor is responsible for reading the temperature. This is necessary for some firmware commands.

Temperature Controller Type

Indicates whether the temperature controller is an extruder or a heated build platform.

Wait for Temperature controller to stabilize before beginning build

If this checkbox is selected, the 3D printer will wait until the set temperature has stabilized before starting to print. This checkbox should always be selected, otherwise the temperature can fluctuate significantly at the start of printing and lead to inconsistent results.

Per-Layer Temperature Setpoints

Here the temperature can be varied individually for each layer. Typically, this setting is used when a different temperature is to be used for the first layer than for the rest of the component in order to optimize adhesion to the build platform