EVO-LIZER 3D printing is fueling the automotive industry

The automotive industry is considered one of the driving industries for additive manufacturing. We experience this almost every day at NEVO3D. The industry's requirements are becoming more and more specific, and the demand for new technical specialty plastics is also increasing.

Additive manufacturing in automotive

In fact, both manufacturers and suppliers in the automotive sector are recognizing the numerous advantages of additive manufacturing. Be it in-house rapid prototyping, final components in small series or rapid tooling, i.e. efficient tool and fixture construction.

The most important advantages

- Leasing helps your liquidity

- Protects equity

- Strengthens your credit rating

- Service included

- Guarantee included

- Guarantees absolute cost security

With the EVO-lizer, NEVO3D offers the automotive industry a highly innovative 3D printer that puts exactly these advantages into practice. Fast, cost-effective and first-class quality. Based on its intelligent and modular concept and our application technology know-how, we adapt both the EVO-lizer and the filament qualities precisely to the respective requirements.

The 3D printers of the EL series offer new possibilities in the automotive industry

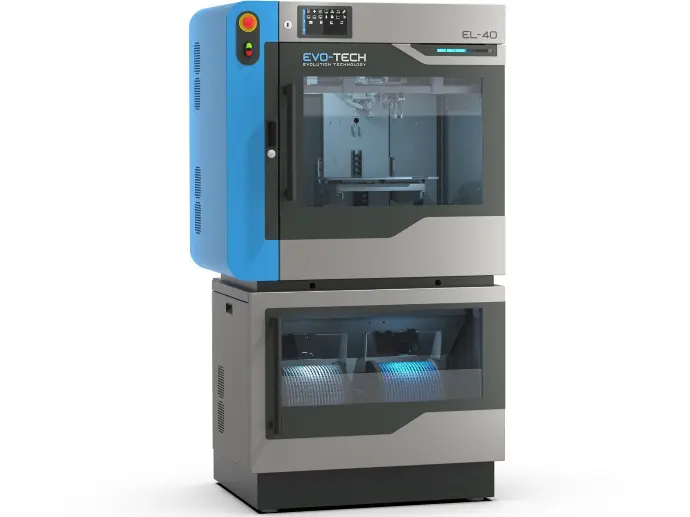

3D printer EL-40

Enables the creation of components up to 270 x 200 x 210mm (W x D x H) with extremely low operating costs and an open system for filaments.

3D printer EL-140

Enables simultaneous printing of multiple components and the processing of large quantities of material up to a size of 570 x 450 x 570 mm (W x D x H).

Excerpt from our customer list in the automotive sector