and the impact on the company

The innovative power in the company increases - the costs for this decrease considerably! This is a unique requirement for all companies and all industries whose success factor depends on innovation! Due to the availability of additive manufacturing in the company and the associated possibilities, low-threshold access to the generation of prototypes is available. In this way, an initial proof of concept of an idea can be created very quickly - the key to further, effective action in the development phase. However, this not only applies to the new development of products but also to in-house device construction, the construction of measuring devices for quality management, laboratory aids, spare parts and much more.

Why make prototypes?

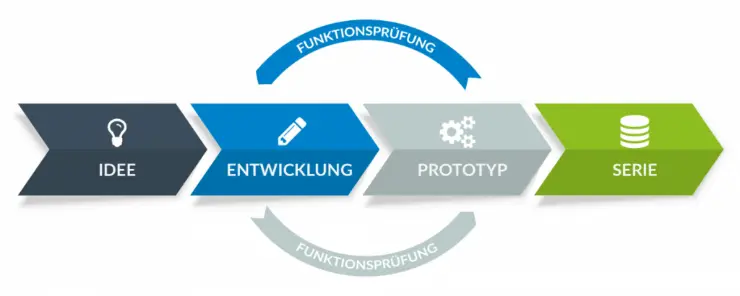

Tight schedules shorten development times. This increases the risk of suboptimal product designs and construction errors, which can lead to significant problems in series production. This logic applies to almost all industries. Be it automobile manufacturing, the electronics industry or machine, tool and device construction.

Implement ideas quickly, cost-effectively and precisely. Identify weak points quickly.

In fact, the EVO-lizer paves low-threshold access for the quick and precise generation of meaningful models. Or to put it another way: initial proofs of concept of ideas can be created quickly, cost-effectively and extremely precisely. Possible errors become immediately apparent. This means that in-house prototype construction is not only indispensable for every company, but also an essential driver of innovation.

Areas of application

- In-house fixture construction

- Measuring devices for quality management

- Laboratory tools

- spare Parts

- and much more

The EVO-lizer series sets new standards in terms of time to market

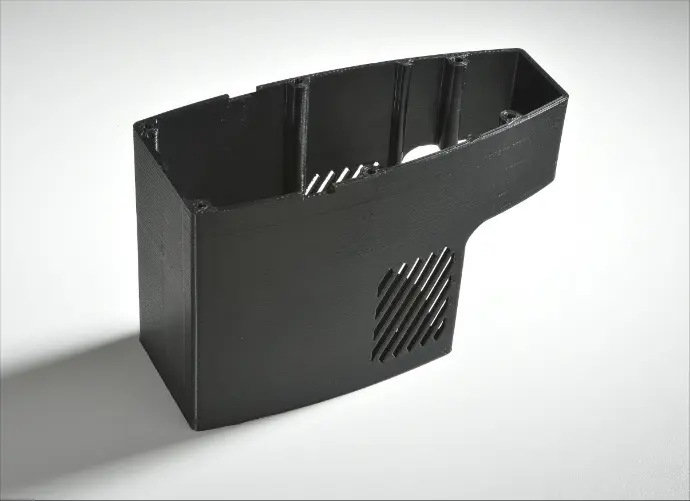

n order to meet today's demands for a realistic time to market adapted to needs, the EL - 3D printer series is irreplaceable in the context of prototype construction. Product cycles are becoming ever shorter and development times must be streamlined. And so that time to market can be reduced to a necessary minimum - without increasing error rates in series production! This primarily applies to prototypes in automobile construction, the development of housings for consumer electronic devices, ergonomics tests of control units, the production of initial samples for trade fairs for product presentations, the demonstration of detailed solutions, such as the RC car development by the CNC Academy or the air distribution system KOLM Engineering.

Precise creation of prototypes with the EVO-lizer 3D printer family

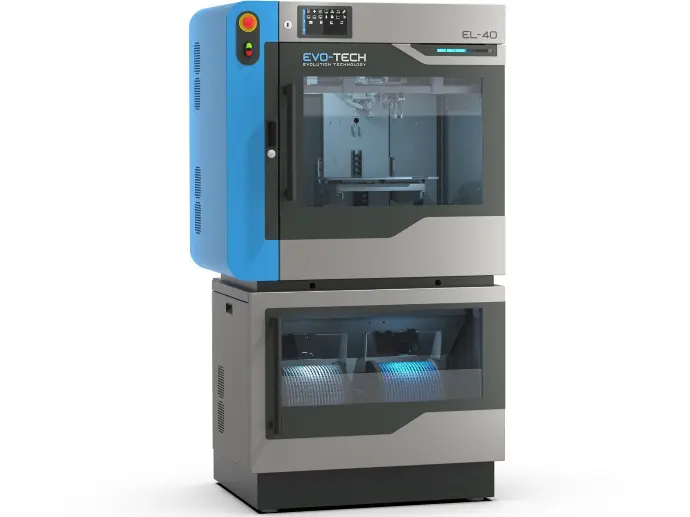

3D printer EL-40

Enables the creation of parts up to 270 x 200 x 210mm (W x D x H) with extremely low operating costs and an open system for filaments.

3D printer EL-140

Enables simultaneous printing of multiple parts and the processing of large quantities of material up to a size of 570 x 450 x 570 mm (W x D x H).

Early detection of errors with prototypes of the EVO-lizer

The bugbear in every product development: errors in prototypes that, in the worst case, extend into series production and cause an enormous cost explosion when corrected. With the use of the EVO-lizer, this development can be prevented - errors in prototypes can be identified early on and revised and solved in the shortest possible time by using more development cycles or several revisions. The launch is not jeopardized, time to market can be maintained!

Design without exploding costs – this is possible with the EL 3D printers!

No matter how experienced the designer may be, it is hardly possible to design the first litter perfectly right away. Having a prototype in your hands can make a lot of things easier - what works, what doesn't work - and why? With the EVO-lizer you remain flexible and can go through a trial and error process several times without having to justify exploding costs or arguing for lengthy release procedures.

See how one of our customers uses the EL-11:

EVO-lizer prototypes – test them in the real world!

With prototypes from our 3D printers, you know exactly what a product will really look like before investing in expensive tools. A lot is possible with the different filaments from NEVO3D! This means that nothing stands in the way of one or more test runs in the real world!