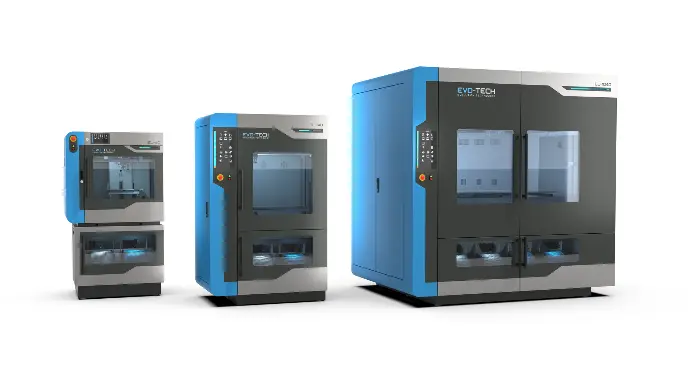

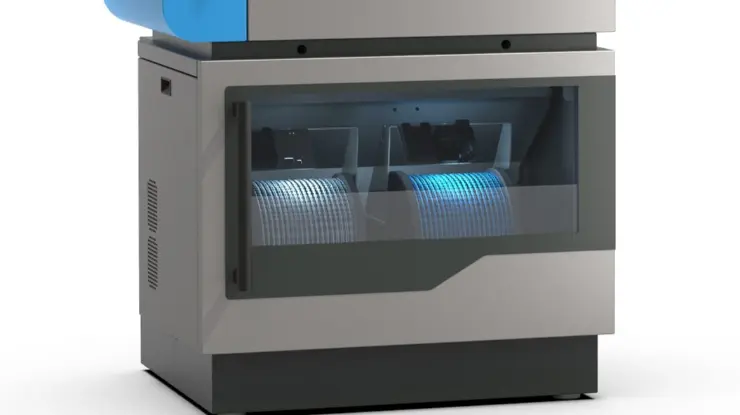

NEVO3D 3D printer

Take the next EVO-lution step in additive manufacturing with us!

The EVO-lizer machine family sets new standards for cost-effective additive manufacturing with industrial functions such as a closed loop drive system, buildchamber heating, material drying and fully automatic calibration. Production in Austria and service branches in Germany allow a direct transfer of know-how to our customers

EVO-lizer 3D printer comparison

EL-40

AB 27.467€

net

Build size: 400 x 260 x 400 mm

Print volume: 40 Liter

Print bed temperature: up to 150°C

Nozzle temperature: up to 360°C

Buildchamber heating: 60°C

Automatic XYZ calibration

Closed loop axis system

Filament run-out sensor

Material detection

Filament drying

Filament spool size: 1 to 10 KG

Soluble support material

Two independent nozzles

Nozzle cleaning station

Copymode

Webcam

Water cooling

-

Magnetic clamping system

Peak power consumption: 2,700 watts

Average power consumption: 900

watts

Electrical connection: 230 volts

Weight: approx. 170 KG

EL-102 V3

AB 64.812€

net

Build size: 500 x 400 x 510 mm

Print volume: 102 Liter

Print bed temperature: up to 200°C

Nozzle temperature: up to 420°C

Buildchamber heating: 100°C

Automatic XYZ calibration

Closed loop axis system

Filament run-out sensor

Material detection

Filament drying

Filament spool size: 1 to 10 KG

Soluble support material

Two independent nozzles

Nozzle cleaning station

Copymode

Webcam

Water cooling

Vacuum clamping table optional

Magnetic clamping system

Peak power consumption: 4,500 watts

Average power consumption: 1,300 watts

Electrical connection: 400 volts

Weight: approx. 500 KG

EL-140

AB 76.692€

net

Build size: 570 x 450 x 570 mm

Print volume: 140 Liter

Print bed temperature: up to 160°C

Nozzle temperature: up to 420°C

Buildchamber heating: 100°C

Automatic XYZ calibration

Closed loop axis system

Filament run-out sensor

Material detection

Filament drying

Filament spool size: 1 to 10 KG

Soluble support material

Two independent nozzles

Nozzle cleaning station

Copymode

Webcam

Water cooling

Vacuum clamping table optional

Magnetic clamping system

Peak power consumption: 4,500 watts

Average power consumption: 1,300 watts

Electrical connection: 400 volts

Weight: approx. 500 KG

EL-1040

AUF ANFRAGE

Contact us!

Build size: 1.300 x 1.000 x 800 mm

Print volume: 1040 Liter

Print bed temperature: up to 160°C

Nozzle temperature: up to 420°C

Buildchamber heating: 100°C

Automatic XYZ calibration

Closed loop axis system

Filament run-out sensor

Material detection

Filament drying

Filament spool size: 1 to 10 KG

Soluble support material

Up to 4 independent nozzles

Nozzle cleaning station

Copymode

Webcam

Water cooling

Vacuum clamping table optional

Magnetic clamping system

Peak power consumption: 9,500 watts

Average power consumption: 4,000 watts

Electrical connection: 400V / 32A

Weight: approx. 2,000 KG

FEATURES

Open system

With our EVO-lizer 3D printers, we offer you the best of both worlds. On the one hand, we have an open system that gives full access to all parameters and allows you to use your own materials. On the other hand, we offer you a variety of our own materials including tested parameters.

Your advantages:

- Good predefined parameter sets

- Independence from the manufacturer

- Lower material costs

- Significantly cheaper “Total Cost of Ownership”

- Open component programming

More Information about open vs. closed systems

Great variety of materials

Whether ESD, soft, hard, UV or heat-resistant - with our 16 materials we always have the right filament solution for you. If this is not the case, you can always use filaments from third-party providers thanks to our open systems.

Your advantages:

- Predefined parameter sets

- Tried and tested filaments

- 1 to 10KG spools

Fully automatic XYZ calibration

Using an integrated tool length sensor, we can measure not only the nozzle height, but also the X and Y deviations of the nozzles from one another.

Your advantages:

- Fully automatic calibration

- High process reliability

- High reproducibility

- No more test prints necessary after changing nozzles

- Better dual printing results

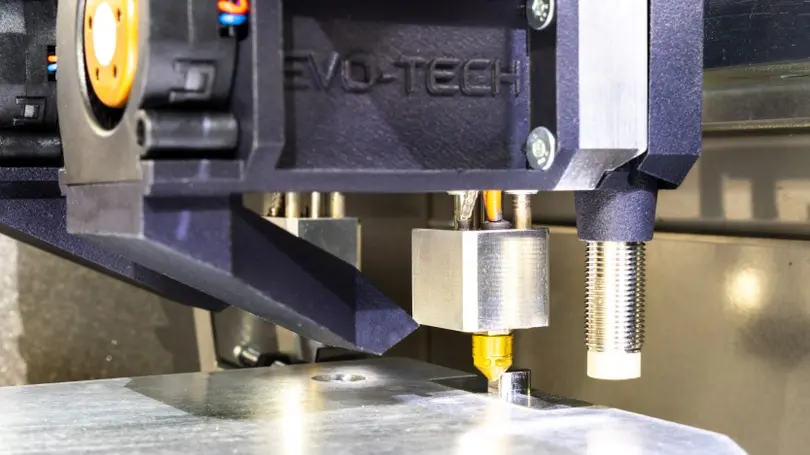

Anti-oozing station for drip-free dual printing

The oozing station prevents material from leaking from one nozzle while another nozzle is printing. This prevents so-called oozing (stringing and dripping on the components).

Your advantages:

- Very good surface quality with dual printing

- High reproducibility

- No material decomposition in the nozzle

- Significantly less cleaning effort

- Shorter printing times

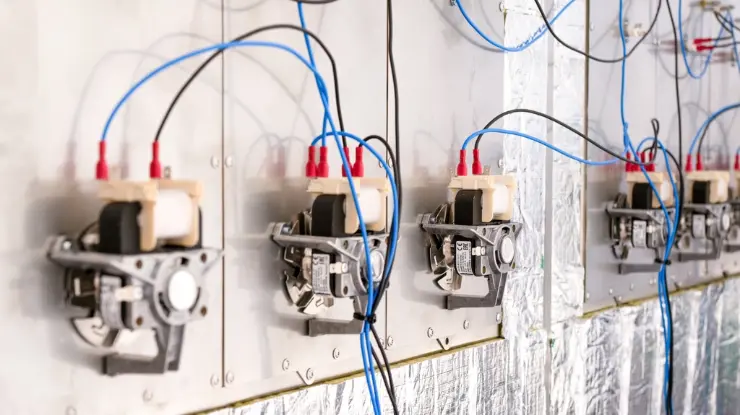

Heated and dried filament chamber

Many filaments absorb humidity from the environment, which can lead to significantly poorer printing results and even print failures. With our integrated drying chamber and its sensors, you can always keep an eye on the moisture and thus increase the quality of your components!

Your advantages:

- Better print quality

- High reproducibility

- Less waste with up to 10 kg of filament

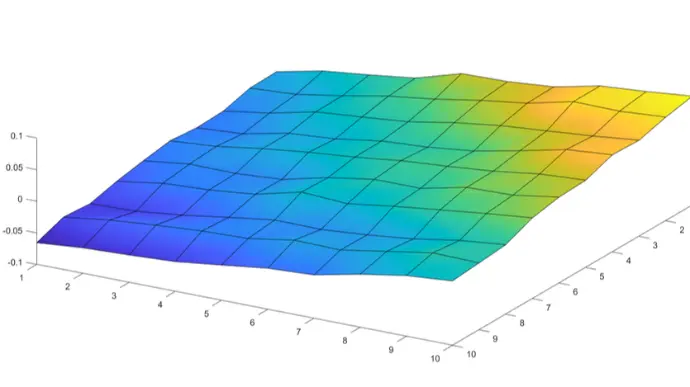

Print bed measurement with up to 121 points

The integrated, inductive sensor measures the evenness of the bed fully automatically before printing starts. Large deviations are corrected before printing by moving the Z axes to one side; small deviations are automatically compensated for during printing.

Your advantages:

- No manual measuring necessary

- High reproducibility

- Better component adhesion

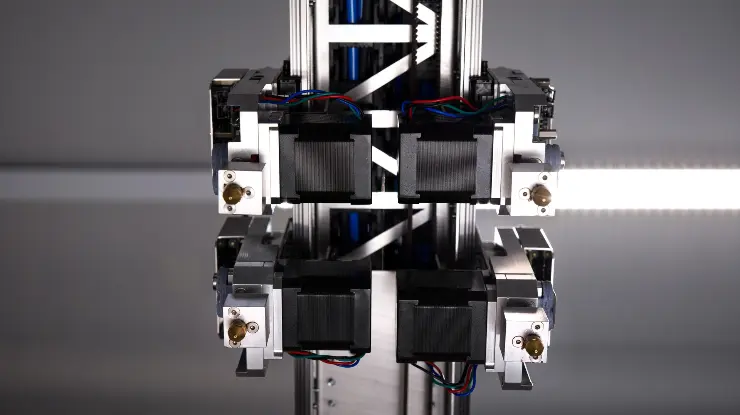

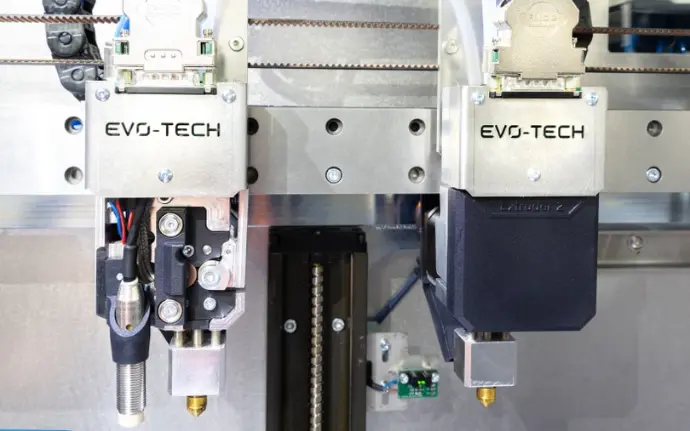

Up to 4 printheads

Increase your productivity with up to 4 printheads that can be used at the same time, as well as the associated output and material combination options.

Your advantages:

- Parallel printing of 4 identical components -> reduction of printing time to a quarter

- Combination of different nozzle diameters -> Fine surface quality for external walls and fast output for filling

- Less set-up times when using different materials regularly

- Combination of up to 4 materials in one print job

M to XXL print area

Your components are not built on sand, but on a neatly milled aluminum plate, which in turn is mounted on a milled steel frame.

Your advantages:

- Prints larger than a Euro pallet are becoming a reality

- Choice between magnetic and/or vacuum clamping system

- Heated printbed minimizes distortion

- No commitment to a manufacturer's proprietary surface material

- Clever linear expansion concept to minimize deformation when heated

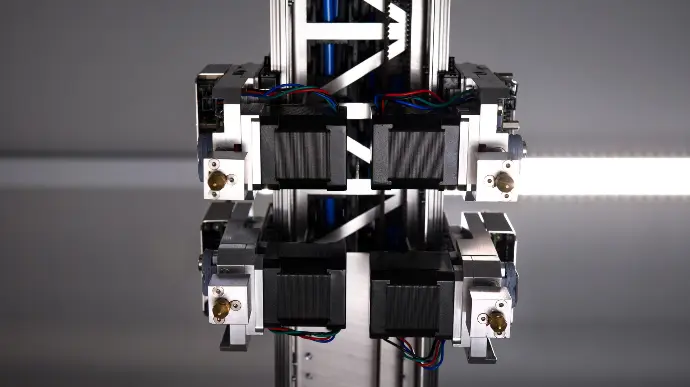

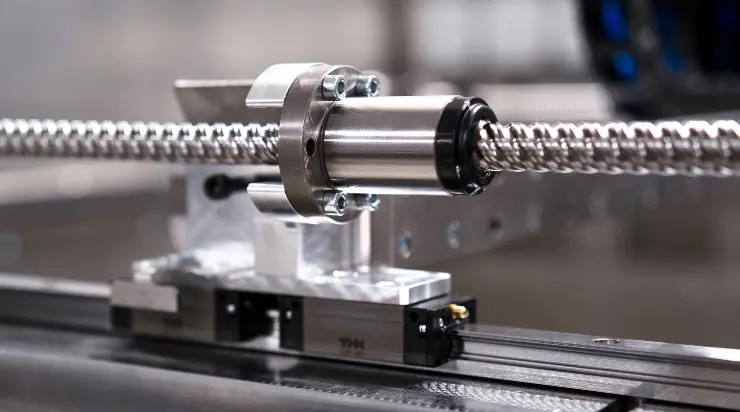

Ball screw, linear guides and reinforced belts

In addition to the design, reproducibility and stability begin with the correct selection of axle components. In 3D printing, in addition to size and dynamics, temperature resistance and linear expansion are also important. With THK we have an industrial partner who can guarantee this.

Your advantages:

- Positioning in the hundredth range

- Low maintenance and wear-resistant

- Hardly any backlash effect

- Industry standard guarantees spare parts availability for decades

- Closed loop drive system

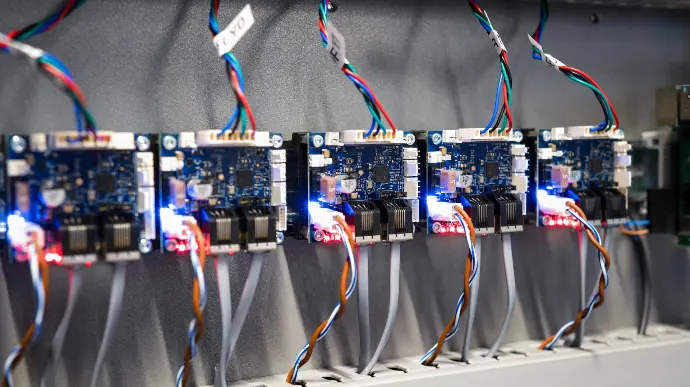

Hardware and software Industry 4.0

Your advantages:

- Upgrade security and easy expandability thanks to the modular CAN bus system

- Communication with G-Code standard

- Automatic updates via Internet or USB stick

- Over 35 sensors ensure a reproducible result

- API for reading real-time data

- UL version available upon request

Up to 7,200 watts make the buildchamber heating glow

When processing plastics in general and in the 3D printing welding process in particular, the process temperatures and controllable cooling are crucial for an excellent result.

In the EL-1040, 6 interior heaters, each with 1,200 watts, ensure comparatively very fast and homogeneous heating of the installation space.

Your advantages:

- Reproducible results

- Significantly less shrinkage and distortion

- Higher component strength

Easy servicing

Your advantages:

- Maintenance points accessible without tools

- Printhead change within minutes

- Nozzle change in seconds