Ultimaker Cura

UPDATES

- The functions and the printing experience are constantly improved through regular updates. If you encounter any problems, please feel free to discuss them with our support! CURA works best with the new generation of machines EL-40V1/EL-102V3/EL-140V1. Older generations of machines should be equipped with an upgrade kit to achieve the best possible printing results!

QUICK TIPS For a high printing success rate!

-

Engineering plastics require a heated build platform and cannot be compared to "hobby" materials, so a RAFT should be used to avoid/minimize warping and elephant feet.

- Uses a RAFT to compensate for imperfections (air bubbles, scratches, etc.) and avoid adhesion problems . Our supp material (SUPPORT) adheres very well between the building platform and many model materials.

- For tall components with a small footprint , a brim should be used instead of raft . In addition, the sacrificial tower diameter and the base area (volume) should be increased so that the tower does not fall over or shear off during printing.

- Not every material had a good SUPP connection (e.g. PETG)!

- If there are adhesion problems between the raft and the model material, the “flow” for the first layer may need to be increased and the speed reduced.

- Direct prints (prints without raft) onto the build platform require a “ Z0 Calibration ” before printing starts.

- Always uses a sacrificial tower/primepillar in dual print. This has essential functions and should always be placed close to the cleaning brushes!

- Pay attention to short distances between components, sacrificial tower and cleaning brushes.

- Uses adhesion promoters if necessary for direct prints (prints without raft), especially for PC/PACF.

- Edged components/corners are bad in 3D printing, use curves in the construction!

- Wall thicknesses should be designed as a multiple of the extrusion width.

- Dual printing is a “must” for the best surface quality of supported surfaces!

- Dual printing requires calibrated tools (T0/T1). Before calibrating, the nozzles must be clean, otherwise measurement errors will occur.

- Use appropriately designed chamfers (pay attention to angles so no support is necessary) for the TOP/BOTTOM areas of your components! This eliminates elephant feet and material overhangs on top layers.

- Check your support structures in slicer. SUPPORT islands should be avoided as they can easily fall over or not adhere to the build platform. CURA offers several solutions for this, such as expanding or connecting support areas.

- Intentionally creates a " sacrificial spot " (bulge with edge) in the "non-visible area" for retracts.

- Place the retracts in one line to create the best possible surface quality!

- Avoid accumulation of material and consider whether TOP/BOTTOM layers are necessary for your component/project! Material and printing time can be saved.

- Print PETG/PLA/PACF/TPU with 75-100% case fan (fan 3), the build space must remain cool!

- PC/PACF/TPU should be dried , otherwise the surfaces will become unclean or print failure may occur.

- Small parts should be printed multiple times/together and not individually to allow the layer to cool.

- Different materials have different shrinkage, which also depends on the component size.

- Foreign material should be printed 15-20°C hotter than the manufacturer's specifications.

- Use copper paste for the heat brakes and nozzle threads. There should be no air gap between the heating block and the nozzle . This can be avoided with copper paste.

- Only use IPA cleaner (Würth) to clean the printing plates.

- Make sure the nozzles are clean before starting printing and before each measurement.

- Components should cool slowly after printing or even follow a “ tempering curve ” to prevent distortion or increase strength.

- Only use fans in exceptional cases, as these have a negative impact on layer adhesion. Fans can significantly improve the quality of overhangs and fine details!

- Nozzle T1 should always be used as a support nozzle. Print GF and CF material with steel nozzles.

- Process parameter sheet contains useful information about our materials regarding specific settings for the different materials(coating, extruder streams, drying, etc.).

- TPE, the extruder flow must be reduced (see process parameter sheet).

- For TPE, the slicer settings for 0.4mm nozzles should be used, but a 0.6mm nozzle should be installed!

- If you change the printing speed, the K factor (Linear Advanced) must be adjusted! Without adjustment, holes or accumulations of material will form at the start or ends of the web.

- Detailed components should be printed with a small nozzle/layer height/speed! Basically, layer height = nozzle diameter/2

-

Slow printing with large nozzle increases strength. More perimeter instead of infill for increased bending strength!

- Whitening, through support or brim removal, can be significantly improved or completely eliminated by subsequent "flaming".

Inside-out prints: Setting has been developed for the best quality of walls (perimeter). Disadvantages are rounder edges, poorer quality of Z-Seam, elephant feet top/bottom layer. Printed parts should be provided with radii and phases to compensate for these disadvantages.

Outside-in prints: Setting is designed for the best quality of overhangs and edges. Advantages are sharp edges, good quality of Z-Seam, reduced elephant feet top/bottom layer. The disadvantage is the reduced quality of walls (perimeters).

Downloads:

A BACKUP file from an EVO-tech CURA account is used as a quick and easy way to install. Please send an email to our support to get the password for your account.

ACCOUNT: support@evo-tech.eu

PW: Please send an email to support@evo-tech.eu

Please send suggestions, bugs and feedback on the profiles to: support@evo-tech.eu

CHANGELOG (last 10 updates):

28.08.2023

14:36

(CURA Version 5.4.0)

Scripts:

- All machines -> Script commands that created unnecessary lines in the G-code have been removed.

- EL-102 V1.5 (Upgrade) -> Cleaning travel adjusted, Z axis is now avoided.

Profiles:

- Quality -> Extrusion widths adjusted.

- Top/Bottom -> Number of top layers increased to 7.

- Infill -> Standard pattern=Triangles Fill level=35%.

- Material -> flow values adjusted.

- Speed -> Speed adjustment for solid infill, external walls, infill, top layer; Acceleration adjustment for external walls and top layer.

- Travel -> Retraction distance adjusted, Retraction speed adjusted, Z-hop adjusted (only when changing tools).

- Support structure -> Outer wall of the structure Switched off by default for better accessibility when breaking out.

- Dual Extrusion -> Position of the prime tower changed to X=340mm / Y=180mm (no more error messages with EL40/EL28).

- Printer Settings -> Heat-up speed and standby temperature time adjusted to hot end inertia.

Cura:

- EL-102 V2 -> Copy mode added

- Materials -> Material values such as “flow” are now correctly written from the designated material table to the selected print profile. If you would like to adjust the flow of a material on your machine or enter your own material profile, do this now via “Materials” in the configuration window. This means that the global flow settings remain unaffected and the flow of the selected material is always adopted in the print job.

- Linear Advance -> All profiles now support Linear Advance

13.07.2023 (CURA Version 5.4.0)

Scripts:

- All machines: In the start code, the raw thread length for the “rinse nozzle” process was reduced from 150mm to 50mm.

- EL-40 V2: “Unnecessary” empty runs were removed from the start code.

- EL-40 V2: “Feedrates” were added to the tool change code to resolve the partial occurrence of slow head changes.

Profiles:

- Now compatible with Cura 5.4.0

Cura:

-

GUI: ABS-Glossy is now displayed in green by default.

Bugs reported:

- There is a “bug” in Cura version 5.4.0 that affects the retraction behavior in the print heads, which sometimes leads to short threads on the prime tower.

- Cleaning cycles: In some cases there is an offset in cleaning cycles (nozzle<->brush). If this occurs with your machine, please let me know: michael.bisewski@evo-tech.eu

27.06.2023 (CURA Version 5.4.1 - beta)

Machines:

- EL-102V2 added back to the machine selection list.

Scripts:

- EL-28 (without upgrade) -> Fixed the bug that the Start/Toolchange script caused a collision with the cleaning station.

- EL-102 V1.5 (Upgrade) -> Fixed the bug that the start script caused a collision with the printing plate.

- All machines -> The error has been fixed where the nozzles did not receive a cool down command after the print job was completed.

Cura:

- Language setting -> Default = English

06.06.2023 14:09 (CURA Version 5.3.1)

- EL-40 V2 fixed an error in the tool change script that caused the print head to move too far to the right during cleaning.

31.05.2023 10:48 (CURA Version 5.3.1)

- Copy mode added for EL-40V1/V2, EL-28V1/Upgradekit, EL-102V2/Upgradekit/V3, EL-140V1

24.05.2023 21:39 (CURA Version 5.3.1)

- Fix bug flow values

- Nozzle values entered correctly under Printer Settings

- Infill legend displayed

23.05.2023 10:46 (CURA Version 5.3.1)

- Retraction default value increased from 1mm to 1.5mm

- ABS matt material profile inserted (manufacturer Kimya)

- Wipe turned off as default

- Dense support for floor turned off as default

- Connect Support turned off as default

- Support top and bottom distance changed from 0.2 to 0.15mm

22.05.2023 09:32 (CURA Version 5.3.1)

- EL-102V1.5 (upgrade kit) cleaning script adapted

19.05.2023 16:30 (CURA Version 5.3.1)

- Update EL-140V1 Tool Change Script

- Update EL-28V1 / EL-40 scripts (Printer Settings and Toolchange)

- EL-102V1.5 (upgrade kit) added

- Bug fix Layer Height 0.4 nozzle from 0.1 to 0.2mm

- General updates to improve surface quality, perimeter welding and overhang printability

-

Reducing the printing speed in the first layer

17.05.2023 11:00 (CURA Version 5.3.1)

- Outside-in profile removed. The customer is responsible for setting inside-out vs. outside-in. Inside-out was set as the default

- Profile for 0.6 and 0.8 nozzles added

11.05.2023 08:27 (CURA Version 5.3.1)

- Support Wall Line Count changed from 0 --> 1

10.05.2023 12:45 (CURA Version 5.3.1)

- ABS temperature settings adjusted

- Fan control implemented as standard

- CURA internal tool change implemented

- Standard profile implemented (faster printing)

- BRIM set as default instead of RAFT

- EL-140 machine settings prepared for comprehensive display updates

OPEN BUGS REPORTED:

Installation note:

Log in with your Evo-tech account and load the backup (restore), this will take over all settings. After loading, please log out and log in with your own account and create your own backup as a first step. EVO-tech profiles must be explicitly selected via the custom tab! Default profiles are not adapted to EVO-tech machines.

Important: Please do not work with the EVO-tech account, create or delete backups. Be careful when using your own account!

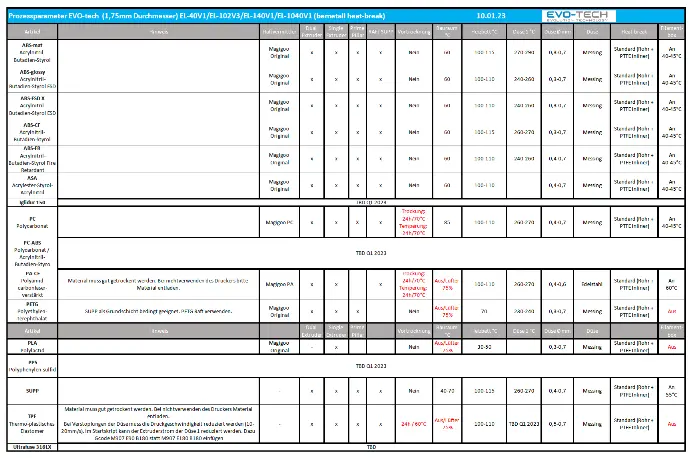

Overview of process parameters

We have created an overview of our materials for you. Particular attention should be paid to drying, adhesion promoters and process temperatures. Some plastics also require a low installation space temperature in order to be processed in a kink-resistant manner.

DISCOVER THE NEW POSSIBILITIES!

Your user interface should look like the image in the background. Printer, machine profile, material profile and plugin list must be installed. With CURA, the full potential of our machines can now be exploited - have fun with it!