3D printing in the railway industry according to EN-45545-2 to R1/HL3 fire protection

From the production of individual parts, from special solutions to series production, 3D printing has become an indispensable part of the “normal” industry. In the railway industry with its high fire protection requirements, 3D printing had a niche existence despite excellent initiatives from, for example, Deutsche Bahn, ÖBB and Siemens. With ULTEM as a material, everything has been technically solved for over 10 years, but applications are usually not economically feasible due to the high machine and material costs. Together with our material supplier KIMYA and the PC-FR R1/H3 we will change this.

Webinar mit ÖBB und KIMYA über 3D Druck in der Bahnindustrie bis zu EN-45545-2 R1/HL3

Erfahren Sie wie die Österreichischen Bundesbahnen 3D Druck einsetzen und was für eine erfolgreiche Zertifizierung nach EN-45545-2 notwendig ist

Our solutions for your additive success

No matter whether you already use a 3D printer and are just missing a cost-effective material or whether you need support from production-friendly design to series production in our 3D printing center. As NEVO3D, we support you from the first component analysis through to the manufactured series assembly.

Component analysis and optimization

We would be happy to evaluate with you whether 3D printing is suitable for components. We analyze design, material and safety requirements according to standard EN-455545-2. Trust in our expertise for optimized product development for additive manufacturing. We would be happy to digitize and design your components for production.

Production of prototypes and series parts

We support our customers with over 20 3D printing machines in the production of individual parts, prototypes and series parts with short delivery times directly from Austria. Additionally, we also offer assembly assembly to efficiently meet your requirements.

Contact us today to realize your projects!

3D printer for your production

We offer our customers customized complete solutions for industrial 3D printers that help them achieve the fire safety standard EN-45545 R1/H3 in their internal production. Our solutions are all manufactured in Austria and are characterized by the combination of certified machines, materials and process parameters.

KIMYA PC-FR filament

The new KIMYA PC-FR filament is the first of its kind to meet the EN-45545 R1/H3 standard. What is particularly noteworthy is that it meets the standard not only for injected samples, but also for 3D printed samples and is certified in the range from 3 to 10 mm.

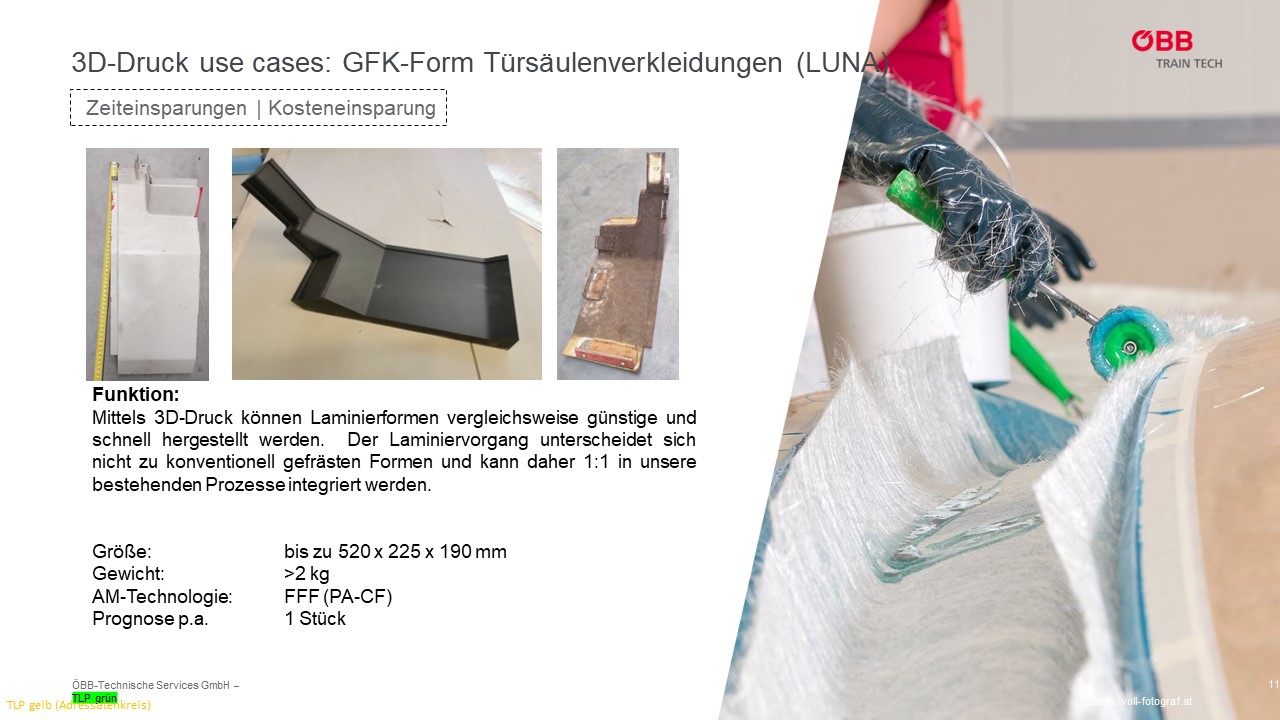

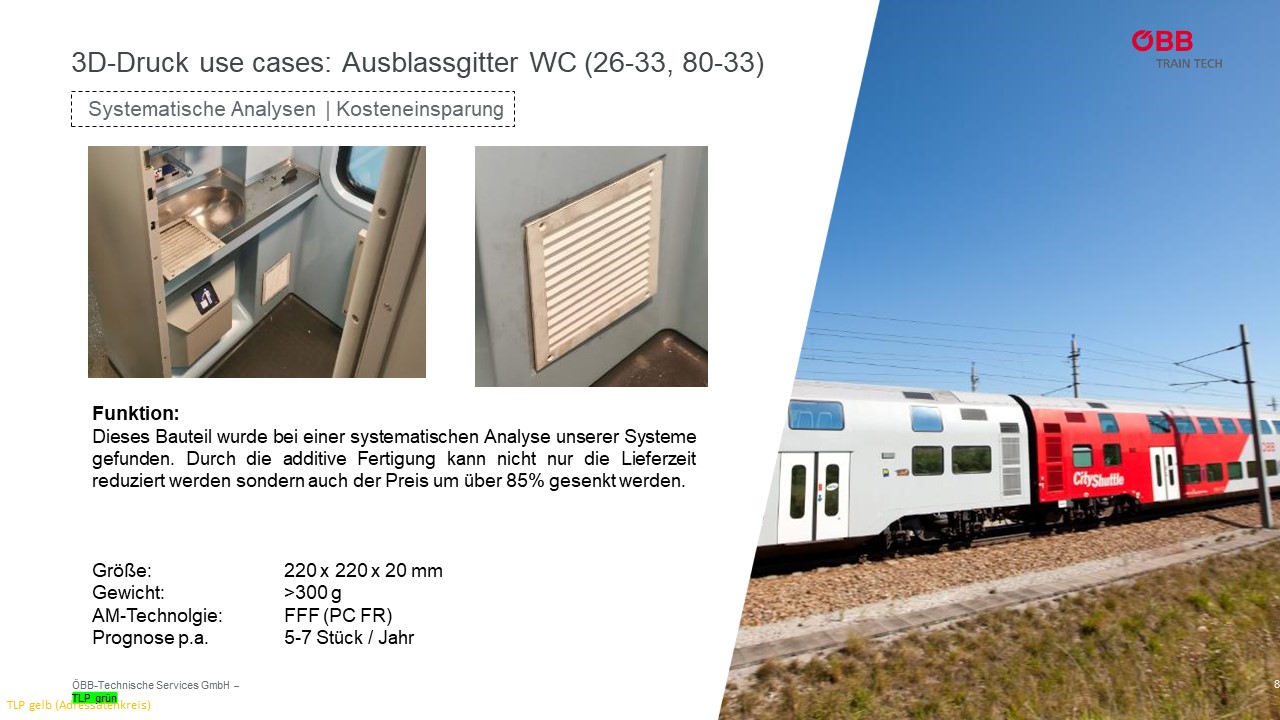

Areas of application of additive manufacturing in the railway industry

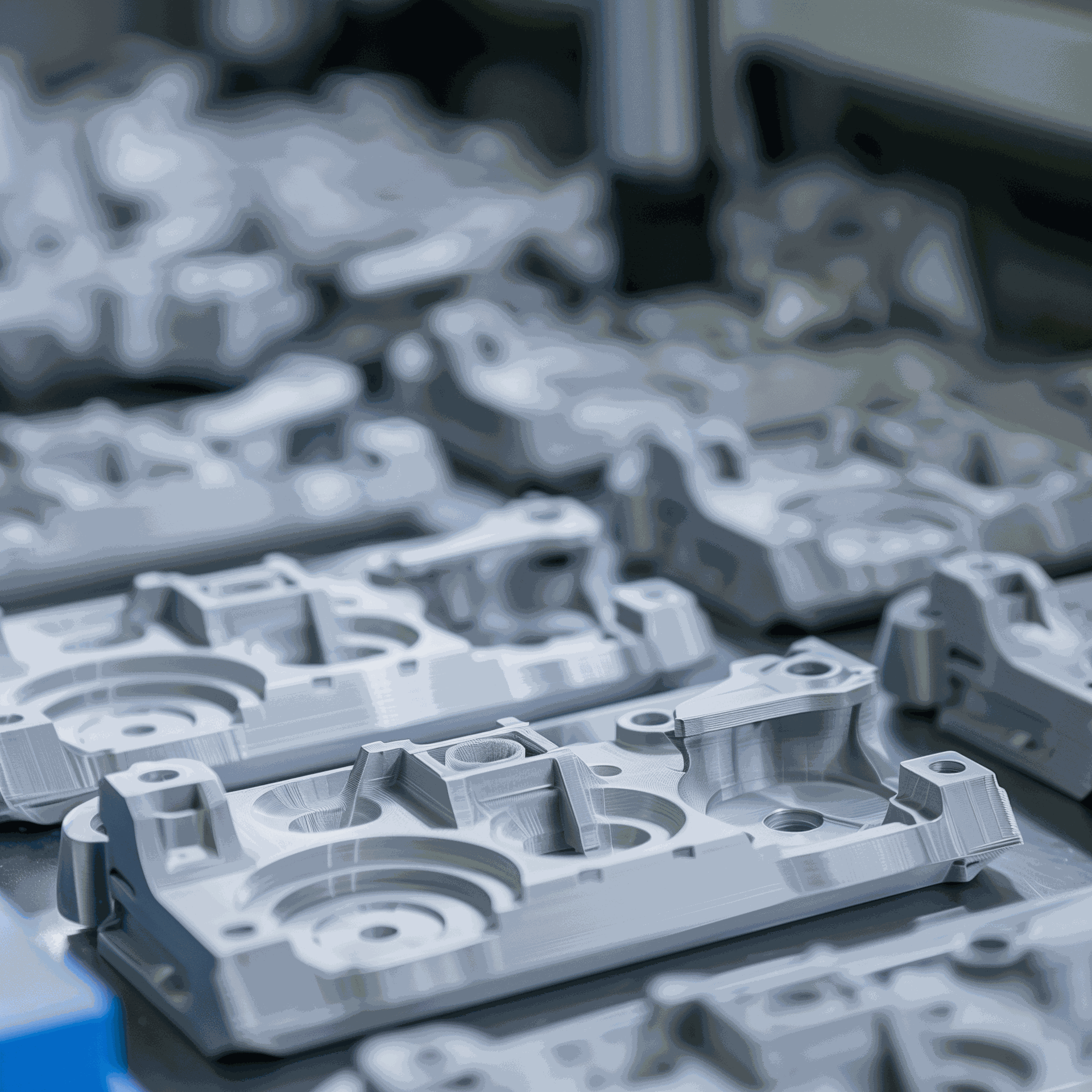

Single part and (small) series production

From the production of individual parts, from special solutions to series production, 3D printing has become an indispensable part of the “normal” industry.

Compliance with the EN-45545-2 standard up to the highest level of R1 HL3 is crucial for the safety and quality of the parts produced. Another advantage is that there are no tool costs for small quantities and a high degree of geometric freedom is guaranteed. This allows complex components to be manufactured efficiently and cost-effectively, which significantly increases flexibility and cost-effectiveness in production.

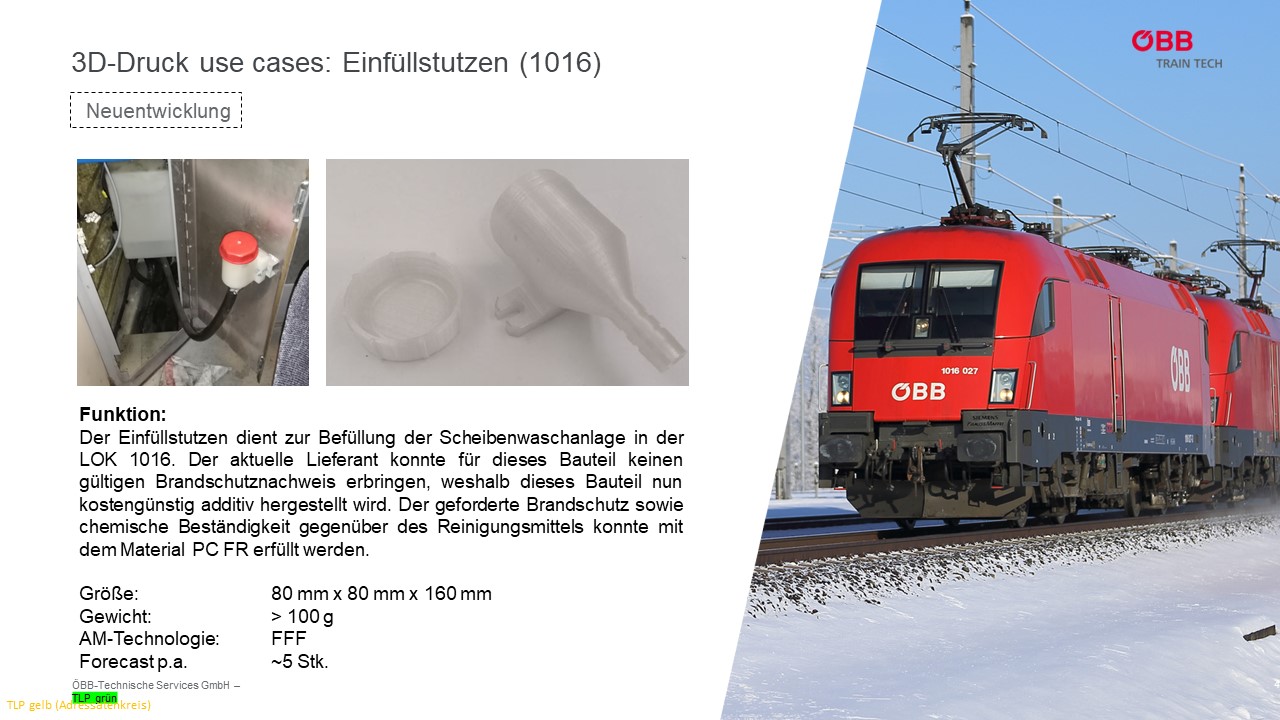

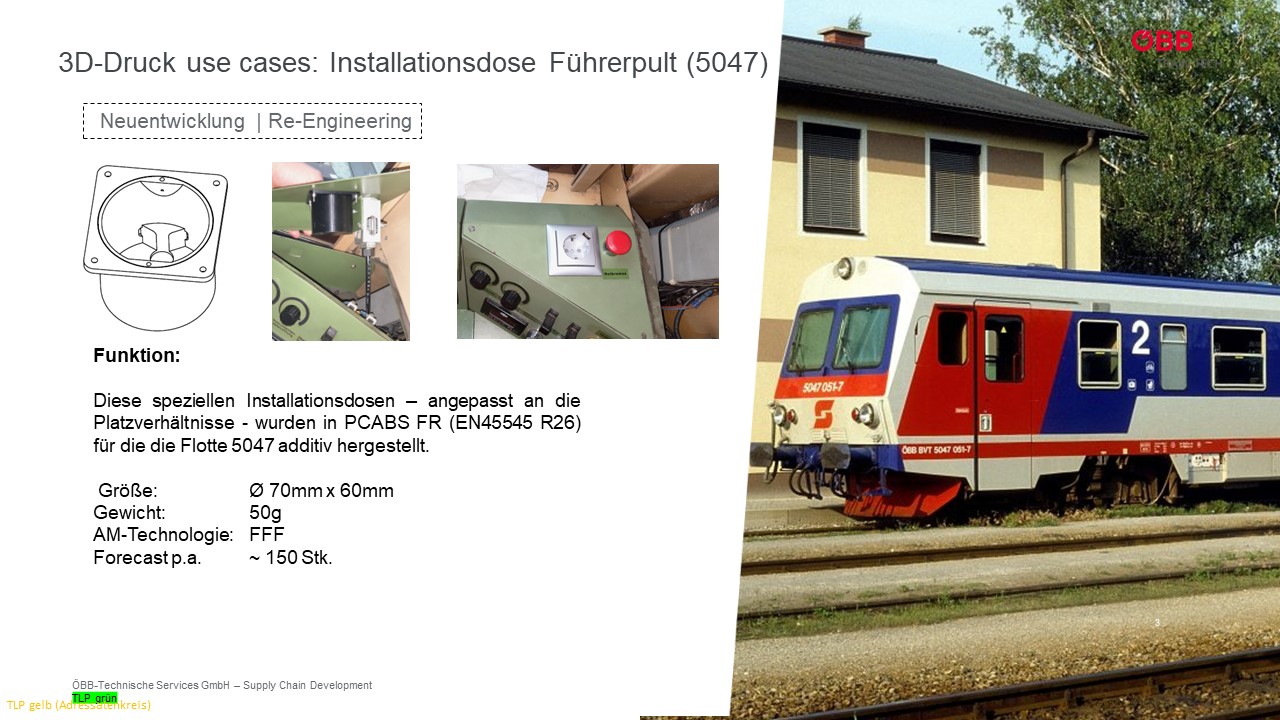

Spare parts production

The railway industry plans very long-term and attaches particular importance to the availability of spare parts, storage costs and downtimes. 3D printing offers a revolutionary solution to increase availability and dramatically reduce inventory and spare parts costs. In addition, 3D printing promotes sustainability, as often only individual parts have to be replaced instead of entire assemblies.

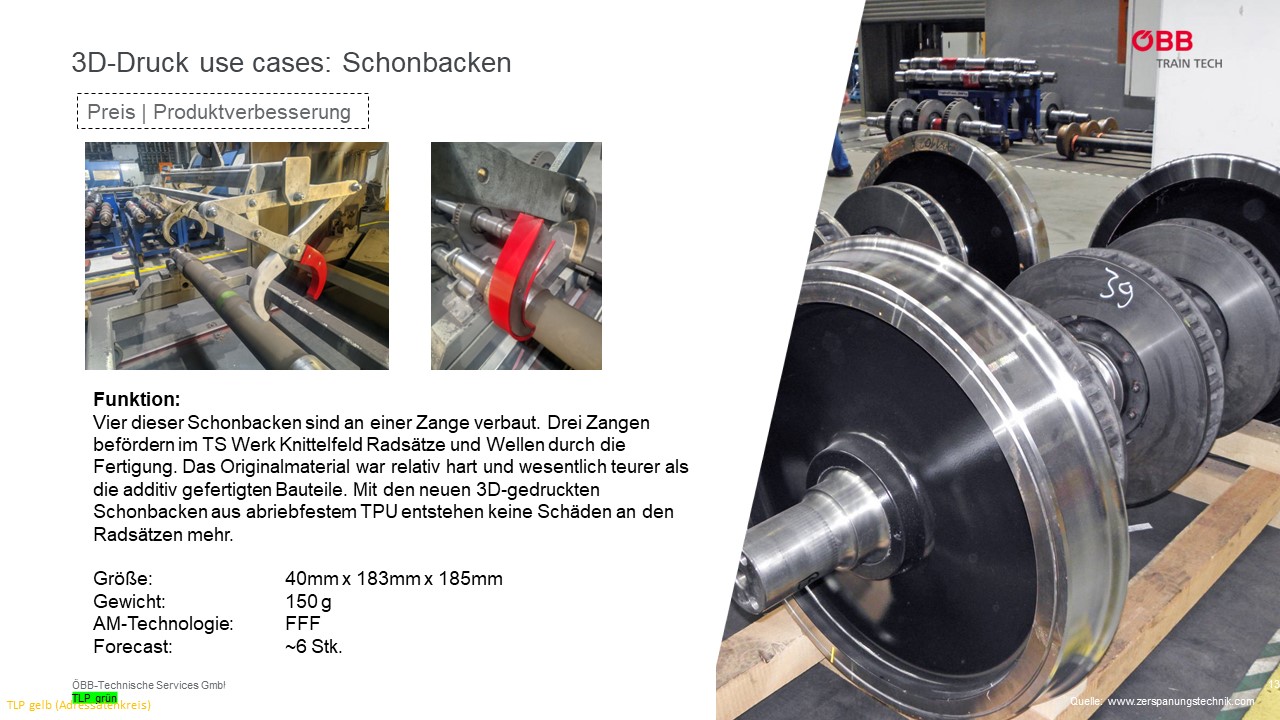

Devices and resources

3D printed devices offer a lot of potential for improvement in the assembly, maintenance and repair of trains. They are particularly impressive due to their high degree of geometric freedom, rapid availability and low costs.

Webinar mit ÖBB und KIMYA über 3D Druck in der Bahnindustrie bis zu EN-45545-2 R1/HL3

Erfahren Sie wie die Österreichischen Bundesbahnen 3D Druck einsetzen und was für eine erfolgreiche Zertifizierung nach EN-45545-2 notwendig ist