User report PMT GmbH

The company PMT GmbH, founded in 2005 and based in North Rhine-Westphalia, advises its customers both during the product development process and when optimizing existing products with regard to the structural design and the use of suitable manufacturing processes and materials.

Additive manufacturing

We started looking into additive manufacturing very early on. We deal with all new manufacturing processes because we always want to offer our customers the best solution for their respective tasks. This sometimes includes abandoning existing production strategies and taking new paths,” says Axel Meier, Managing Director of PMT.

“When implementing projects, we examine the optimal technology for our customers at the most affordable price. We find the most cost-effective manufacturing process for the component and/or assembly. We also take care of a smooth change in manufacturing technology for existing components, provided this is an economic advantage for our customer.

“We consider 3D printing to be a technology of the future and would like to help shape the future in this area. In our opinion, additive manufacturing is still in its infancy and we therefore see huge potential here.”

Axel Meier, Managing Director of PMT GmbH

Economical production of small batch sizes

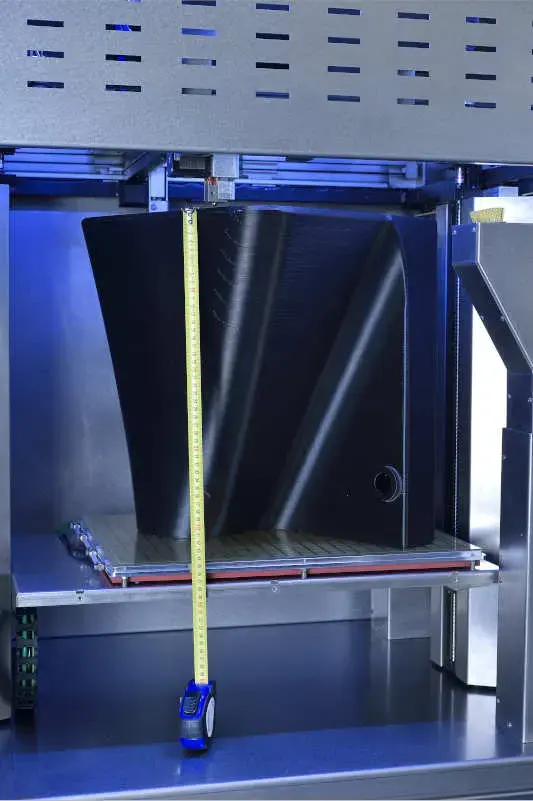

It has already been possible to design a customer's existing gripper components in such a way that weight and cost savings were possible. However, the possibilities of the new EL-102 only became apparent in a more recent project. “A customer in the feed industry needed housings for a control device. Such housings must meet certain framework conditions that can only be achieved with an adapted housing design. Unfortunately, standard housings are not suitable for this purpose and producing an injection mold for this would go far beyond the budget given the low batch sizes. In this case, a 3D printed case was the first choice. With the EL-102 from EVO-tech it was possible to provide the two housing parts quickly and cost-effectively. Given the low batch size, in our opinion it’s actually the only economically sensible approach,” says Meier happily.

“The challenge with parts of this size is that any manufacturing-related component distortion has a direct impact on the function. With our installation space temperature control and a stable construction process, we were able to manufacture the housing components with our machine in such a way that all parts fit together,” adds Kaltenbrunner.

FFF process with great potential

Meier currently sees the greatest potential for such applications in the FFF process because the variety of materials and the comparatively low machine costs represent the most economical combination for him. “We are happy to have found a partner in NEVO3D who not only delivers solid machine technology, but also quickly helps us with questions and offers good technical service,” says the PMT managing director, praising the collaboration with NEVO3D.

“Reproducibility and therefore the ability to produce series parts is a central challenge in additive manufacturing. With the EL-102 we are taking a big step forward in this regard.”

Markus Kaltenbrunner, Salesmanager of NEVO3D GmbH

3D printer EL-140

Allows you to print multiple parts at the same time and process large quantities of material up to a size of 500 x 400 x 510 mm (W x D x H).