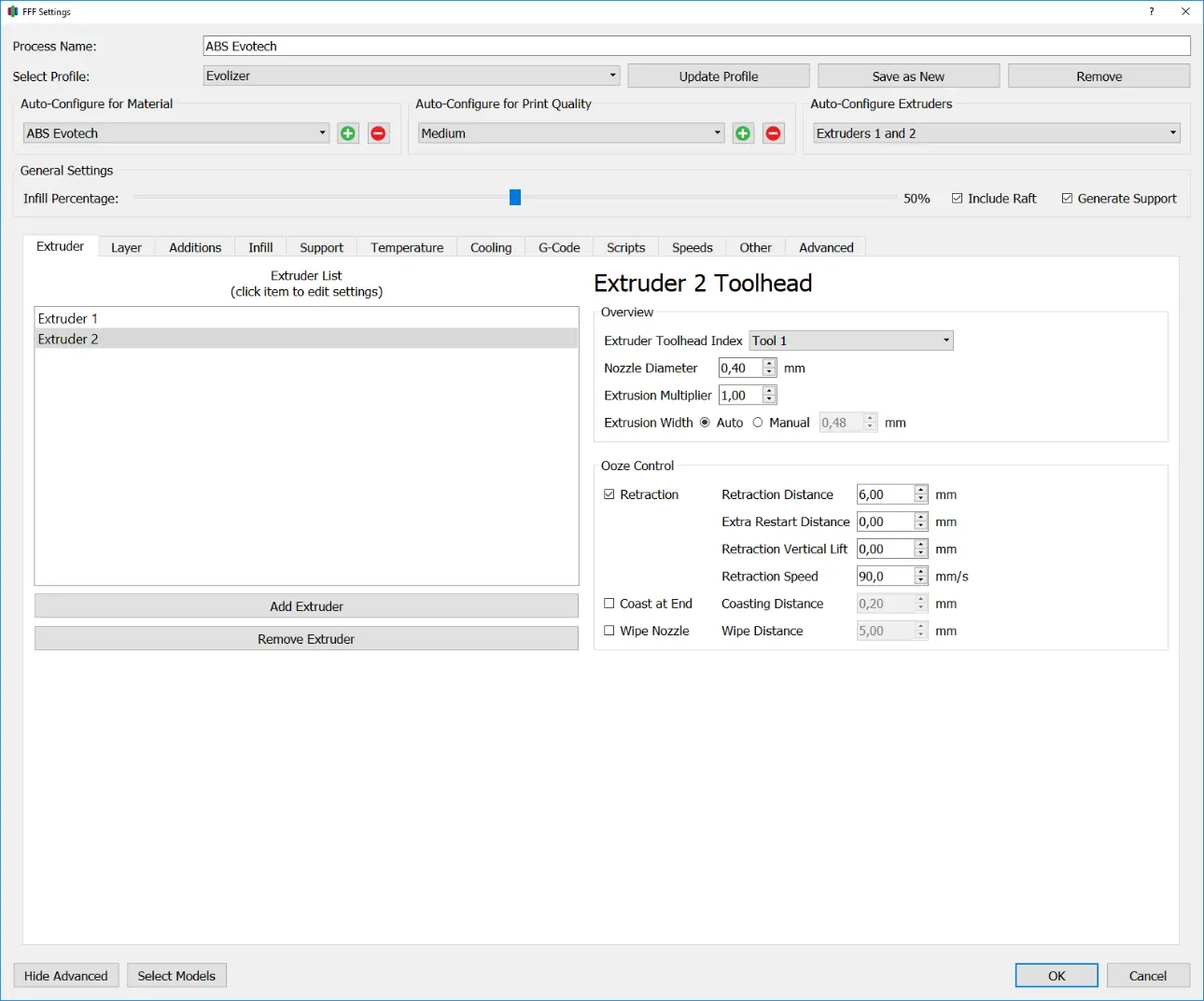

Overview Section

Extruder Toolhead Index:

This parameter indicates the number of the extruder. Using this index, the firmware knows which motor is responsible for feeding the filament, which temperature sensor reads the temperature and which heating unit is responsible for reaching the processing temperature.

Nozzle Diameter

The diameter of the nozzle used affects the print speed and level of detail. With a larger nozzle, thicker and wider webs can be printed, which reduces printing time, but fine details are usually lost in the process. As a rule, components manufactured with larger nozzles are more stable, but it can happen that cavities arise in the component due to the way the tool paths are laid, which would not have occurred if a smaller nozzle were used. (Details in the sub-sections “ Thin Wall Behavior” and “ Single Extrusion ”)

Extrusion Multiplier

The extrusion multiplier changes the rate at which the filament is advanced and thus the volume flow that exits the nozzle. Before changing this parameter, you should first check whether the filament is extruded at the correct temperature and whether the gear of the feed unit is intact and clean. If both are given, the extrusion multiplier is a simple solution for over- or under-extrusion. The value should not differ from 1 by more than 0.2. Above or below this, the filament diameter should be checked for excessive deviations.

Extrusion Width

The Extrusion Width indicates how wide a line drawn by the 3D printer is. The extrusion width takes into account the fact that plastic melts tend to expand when emerging from narrow cross-sections, such as the nozzle of a 3D printer (Barrus effect). The “Auto” setting takes the nozzle diameter and multiplies it by 1.2. This is a good guideline value for nozzle diameters under 0.8 mm, for larger nozzles the value should be set by the user using the “Manual” tab.

Normal: 1.2 times the nozzle diameter

Minimum: 1.1 times the nozzle diameter

Maximum: depending on the nozzle geometry, up to 1.5 times the nozzle diameter

Ooze Control

Retraction

Retraction refers to the pulling back of the filament when moving the print head without extrusion. This is done to avoid phenomena such as “stringing”, the dragging of fine threads on very tough filaments, as well as “blobs”, small plastic chunks that form at the nozzle tip during the process and then stick to the component, by reducing the pressure from the filament is taken.

Retraction Distance

The retraction distance indicates how far the filament is retracted. Since the distance between the feed unit and the hot end is much larger in Bowden extruders than in direct extruders (see Bowden vs. Direct) and the filament is therefore compressed over a larger area, the value for these systems should also be correspondingly larger . For direct extruders, 1 mm is a good guideline; for Bowden systems, around 6 mm should be chosen.

Extra Restart Distance

This value indicates how much filament should be extruded after the process in addition to that withdrawn and should only be used if defects occur after the process.

Retraction Vertical Lift

This value indicates how far the print head moves away from the component in the z direction when performing a retraction. This can help prevent marks on the component caused by the nozzle grazing over the top layer.

Retraction Speed

This value indicates the speed at which the filament is retracted.

Coast at End

This value indicates how far the extrusion of the filament is stopped before the print head is set down. The remaining distance until settling is then bridged with the pressure still in the nozzle.

Wipe Nozzle

This parameter indicates how far the nozzle is wiped. After the outermost perimeter is pulled and the filament is retracted through the retract settings, there may still be a small amount of plastic at the tip of the nozzle. This is then wiped off by moving the nozzle over the already printed area.